Audio for slide 3 (mp3)

Audio for slide 3 (mp3)

There are some situations where electrostatic discharge (ESD) inside a room can cause problems. ESD occurs when there is a sudden flow of electricity between two objects. You can generate static electricity by rubbing certain materials together, or scraping a chair on the floor, or even walking across a floor if your shoes and the floor surface are made of particular materials.

Audio for slide 4 (mp3)

Audio for slide 4 (mp3)

Before you undertake this unit The content material in this unit follows on from the topics covered in the following two units: Commercial vinyl Lay flat vinyl. If you haven't already completed these units, you should go to them now and read up on general techniques of installing resilient sheet products, along with the discussions on safety, adhesives and tools.

Audio for slide 6 (mp3)

Audio for slide 6 (mp3)

When an electrically charged object is brought near an object that conducts electricity but is separated from the ground, there will be a discharge as the electrons jump across. If the charge is strong enough, there may be a spark or 'crack' sound. But even a tiny discharge, too small for a person to notice, can disturb sensitive electronic components or cause equipment failures.

Audio for slide 7 (mp3)

Audio for slide 7 (mp3)

This is why floors in areas that house sensitive electronic equipment need to be 'ESD safe'. In critical applications, ESD floors are used in conjunction with other measures, such as humidity controllers and 'static controlled' clothing and footwear.

Audio for slide 8 (mp3)

Audio for slide 8 (mp3)

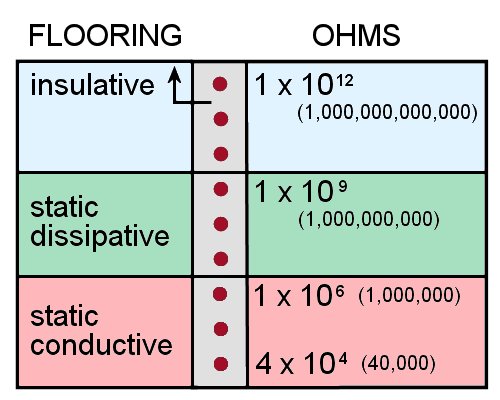

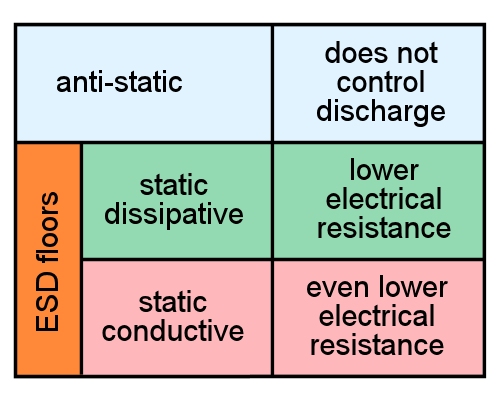

Dealing with static electricity Resilient floor coverings can be grouped into three basic categories to describe their ability to deal with the problem of static electricity - anti-static, static dissipative and static conductive.

Audio for slide 9 (mp3)

Audio for slide 9 (mp3)

Anti-static Anti-static floors are made from materials that do not generate a static charge. In that sense, an ordinary linoleum floor is 'anti-static' under certain conditions, and so is bare concrete as long as the relative humidity in the floor and air are balanced correctly. But there is also a wide range of tile and sheet products specifically marketed as anti-static because they do not contribute to the build-up of static electricity, unlike many normal vinyl and carpet products.

Audio for slide 10 (mp3)

Audio for slide 10 (mp3)

They are often used in the picking and packing areas of warehouses and around automated carousels. Although anti-static floors overcome the problem of people building up a static charge as they walk across the floor, they won't actively attract or control a charge before it has a chance to discharge somewhere else. For this reason, they are not classified as 'ESD flooring'. This term is reserved for static dissipative and static conductive flooring.

Audio for slide 11 (mp3)

Audio for slide 11 (mp3)

Static dissipative Static dissipative floors allow static electricity to 'dissipate', or discharge in a controlled way. They're used where a higher level of static control is necessary, such as in computer rooms, x-ray suites, operating theatres and some electronics manufacturing facilities. In technical terms, a static dissipative floor is defined as having a surface resistance of between 1 x 106 ohms and 1 x 109 ohms. (See below for details on surface resistance in floors.)

Audio for slide 12 (mp3)

Audio for slide 12 (mp3)

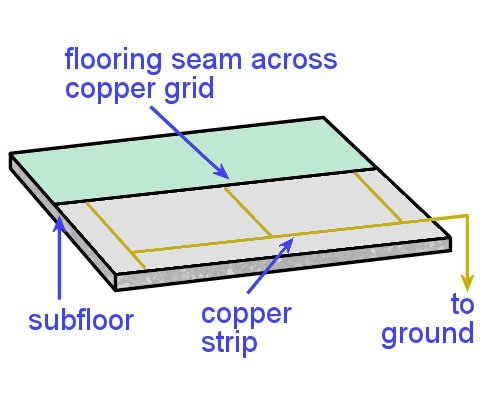

Static conductive These floors are at the top level of ESD flooring, and are more conductive than static dissipative floors. They are used in places where very sensitive components are being handled, such as on electronic assembly lines. Conductivity is improved by installing the floor over a grid of copper tape and earthing it to the ground. The surface resistance of static conductive floors is defined as being between 4 x 104 ohms and 1 x 106 ohms.

Audio for slide 13 (mp3)

Audio for slide 13 (mp3)

What does surface resistance mean? The surface resistance of a floor refers to how easily an electric charge can travel across its surface. The higher the resistance, the more 'insulative' it is. The lower the resistance, the more 'conductive' it is. An insulative material is one that has a surface resistance of greater than 1 x 1012 ohms. 1012 is another way of saying one trillion (that is: 1,000,000,000,000 - or 1 with 12 zeros after it). An ohm is the unit of measure for the electrical resistance between two points. Its symbol is Ω.

Audio for slide 14 (mp3)

Audio for slide 14 (mp3)

To remove the problem of electrostatic damage to sensitive equipment, a floor needs to have low electrical resistance so that any static electricity generated is able to be discharged before it has a chance to build up. This is what characterises an ESD floor. Unlike ESD floors, anti-static floors aren't officially described in terms of surface resistance, because their purpose is not to control the discharge of static electricity - it's simply to reduce the build-up in the first place. Nonetheless, the floor coverings that can be classed as anti-static are generally in the range 1010 ohms to 1012 ohms.

Audio for slide 15 (mp3)

Audio for slide 15 (mp3)

For floors that do need to be ESD safe, engineers often specify actual surface resistance levels rather than simply calling them 'static dissipative' or 'static conductive'. For example, hospitals typically have ESD floors specified at somewhere between 5 x 104 ohms and 2 x 106 ohms. Computer companies have varying requirements depending on what they do, but the specifications tend to go up to 1 x 109 ohms.

Audio for slide 17 (mp3)

Audio for slide 17 (mp3)

If a client asks you for 'anti-static flooring', you need to find out exactly what the purpose of this 'static control' is. If it's just to stop the problem of people getting a tiny shock when they touch something due to a static build-up, then an anti-static floor covering is the most appropriate choice.

Audio for slide 18 (mp3)

Audio for slide 18 (mp3)

However, if they're using or handling components that could be damaged by electrostatic discharges, you need to ask more questions and find out what level of protection is required. The manufacturers of the equipment being used in the room are likely to specify the type of flooring required. In the case of new buildings or facilities, there are sure to be engineering specifications for any ESD-sensitive areas.

Audio for slide 19 (mp3)

Audio for slide 19 (mp3)

The techniques used to install anti-static flooring are the same as for any other tile or sheet installation. However, the composition of the product may be somewhat different, so you should strictly follow the manufacturer's instructions on the correct adhesive and underlayment to use. The manufacturer may also provide advice on the most appropriate trims and other fittings for this type of floor.

Audio for slide 20 (mp3)

Audio for slide 20 (mp3)

Static dissipative floors If it turns out that the client needs a static dissipative floor, you can still use the same general installation techniques. However, the following differences will apply: the flooring material selected must have a surface resistance specification that puts it in the static dissipative category the adhesive must also have a low resistance specification and strictly comply with the manufacturer's requirements the levelling compound and subfloor may have to meet certain specifications to ensure that they won't affect the floor's ability to dissipate static charges under some circumstances, the floor may need to be earthed by a licensed electrician.

Audio for slide 22 (mp3)

Audio for slide 22 (mp3)

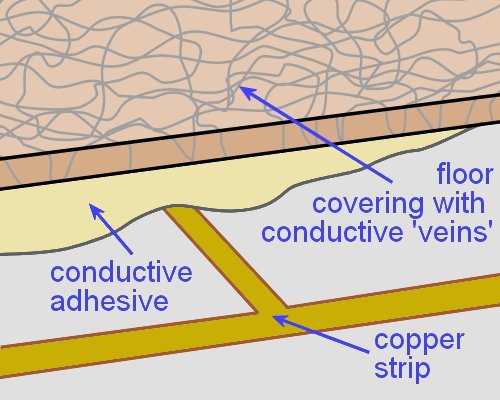

As we discussed earlier (in 'Static electricity in floors'), conductive floors have a low electrical resistance. This is achieved through adding thousands of tiny conductive fibres or 'veins' into the tile or sheet product. Depending on the brand of flooring, these conductive fibres or chips could be made of carbon, graphite, metal, or a combination of materials. The structure of the resilient product is homogeneous, to ensure that the fibres are evenly distributed throughout.

Audio for slide 23 (mp3)

Audio for slide 23 (mp3)

Installation method To install a conductive floor, you should follow the manufacturer's instructions precisely. There may also be additional building specifications that you need to comply with in the ESD safe area.

Audio for slide 24 (mp3)

Audio for slide 24 (mp3)

Here is the general procedure. Apply a primer to the floor with a brush or roller. Depending on the manufacturer and the size of the floor area, you may need to use a conductive primer. Stick down the copper strip in the grid pattern specified by the manufacturer, and run it across to the earthing point on the wall. Use a conductive adhesive to stick down the flooring, and roll the floor with an appropriate sized roller. Check the electrical conductivity, and organise for a licensed electrician to earth the connection.