Concrete slab subfloors

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

Concrete slabs are very popular in project homes and commercial buildings, especially in ground floor construction.

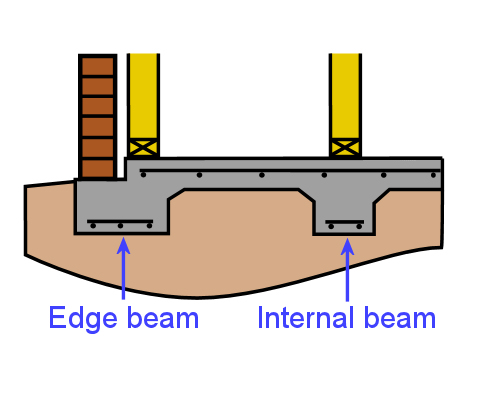

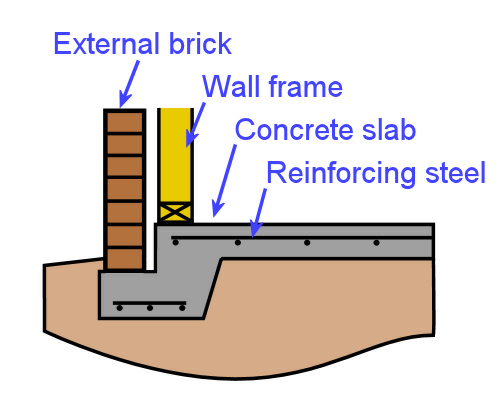

This drawing shows a cross section of a typical on-ground slab for a brick veneer building.

You can see that there's an external skin of brickwork and an internal wall frame in timber or steel.

Because brickwork is porous and absorbs moisture, there is a cavity between the external and internal skins to stop moisture from seeping through and reaching the inside wall.

This drawing shows a cross section of a typical on-ground slab for a brick veneer building.

You can see that there's an external skin of brickwork and an internal wall frame in timber or steel.

Because brickwork is porous and absorbs moisture, there is a cavity between the external and internal skins to stop moisture from seeping through and reaching the inside wall.

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

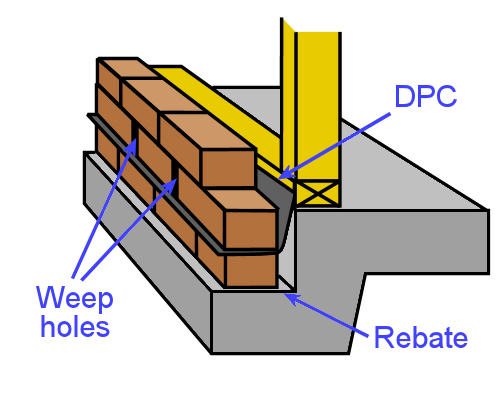

Near the bottom of the cavity is a damp proof course (DPC), also called flashing, which runs around the full perimeter of the building.

Any moisture that does seep in through the bricks is caught by the DPC and channelled back outside through weep holes.

The brickwork sits on a rebate in the concrete, which helps to protect the inside floor from moisture penetration.

Any moisture that does seep in through the bricks is caught by the DPC and channelled back outside through weep holes.

The brickwork sits on a rebate in the concrete, which helps to protect the inside floor from moisture penetration.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

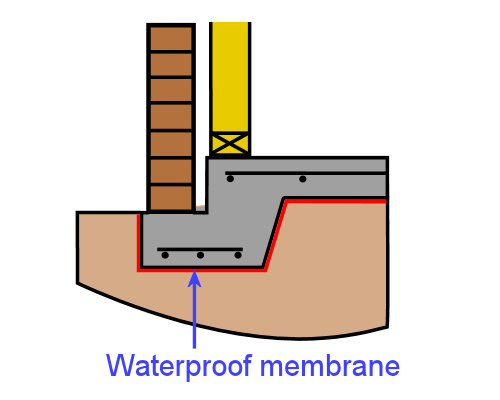

Underneath the slab is a waterproof membrane, also called a vapour barrier.

Its purpose is to stop moisture in the soil from being drawn into the underside or sides of the slab.

If moisture was allowed to enter, it would slowly rise to the top of the slab and cause moisture problems in the floor.

In residential construction, on-ground slabs are generally 100 mm thick, with increased thickness at the edges and wherever extra strength is required internally.

Its purpose is to stop moisture in the soil from being drawn into the underside or sides of the slab.

If moisture was allowed to enter, it would slowly rise to the top of the slab and cause moisture problems in the floor.

In residential construction, on-ground slabs are generally 100 mm thick, with increased thickness at the edges and wherever extra strength is required internally.

Audio for slide 6 (mp3 |6|KB)

Audio for slide 6 (mp3 |6|KB)

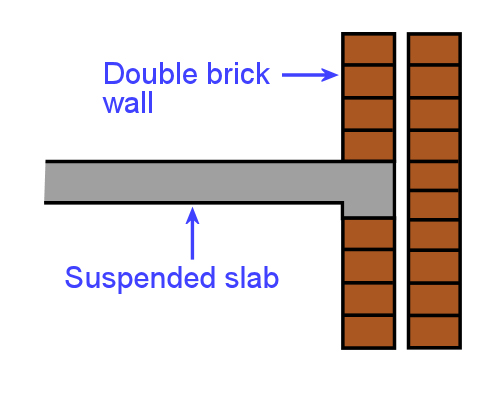

Suspended slabs are often used in upper floors of buildings.

Because of their weight, the internal supporting wall needs to be stronger than a timber frame, so they're generally supported by brickwork.

This drawing shows a cavity brick or double brick wall, with the slab protected from moisture by the cavity between the two 'leaves'.

Because of their weight, the internal supporting wall needs to be stronger than a timber frame, so they're generally supported by brickwork.

This drawing shows a cavity brick or double brick wall, with the slab protected from moisture by the cavity between the two 'leaves'.

Audio for slide 7 (mp3 |6|KB)

Audio for slide 7 (mp3 |6|KB)

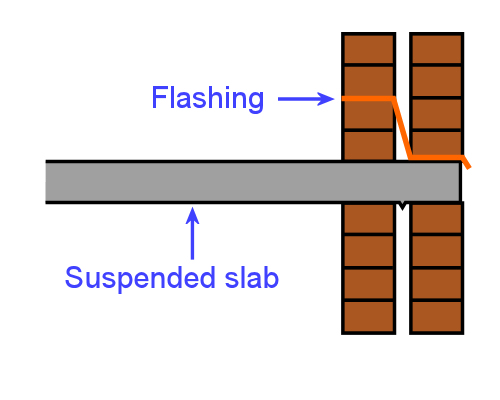

Sometimes in commercial buildings or multi-storey flats, the suspended slab is supported by both leaves of the double brick wall.

In this case, flashing is used to collect any moisture that runs down the inside of the external wall.

There is also a 'V' in the underside of the slab to stop water from running across to the internal wall.

In this case, flashing is used to collect any moisture that runs down the inside of the external wall.

There is also a 'V' in the underside of the slab to stop water from running across to the internal wall.

Learning activity

Audio for slide 8 (mp3 |6|KB)

Audio for slide 8 (mp3 |6|KB)

Flashing is sold in rolls and comes in a variety of materials. It's not only used at floor level in a wall, but is built into the structure under window sills, on roofs (especially around chimneys, skylights and vents) and in various other places where joints might allow water to penetrate.

Do you know what materials flashing is made from? See if you can name at least three different types of materials. Which one is most common around the base of an external brick wall?

Go to Timber framed subfloors

Go to Timber framed subfloors