Structural sheet flooring

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

Particleboard

Particleboard is also called chipboard, because it's made from small chips of wood glued together and compressed in a high-temperature press.

Different types of formaldehyde glue are used in different grades of particleboard, depending on the end use of the product and the performance that's expected of it.

In the case of flooring, the glue is high strength phenol formaldehyde.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

This gives the builder time to put down a platform floor and then install the wall frames, roof trusses, cladding and roof covering.

The flooring is glued to the joists and nailed to help secure the sheets while the glue sets.

Audio for slide 6 (mp3 |6|KB)

Audio for slide 6 (mp3 |6|KB)

However, for the flooring to be successful in wet areas it needs to be well protected from moisture with the use of flashing, surface sealants and careful building techniques.

An alternative product in wet areas is compressed fibre cement, which is much more resistant to water.

Audio for slide 7 (mp3 |6|KB)

Audio for slide 7 (mp3 |6|KB)

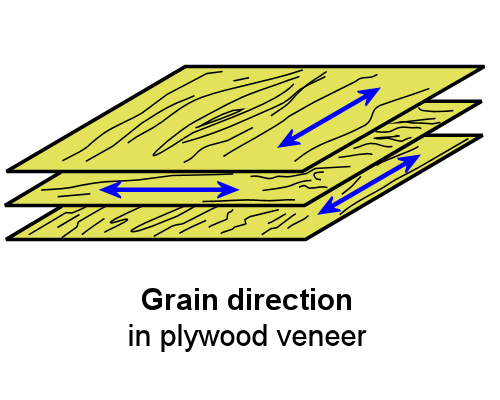

Plywood

Plywood is made up of several 'plies', or layers of wood veneer, glued together and bonded in a high temperature press.

The direction of the grain in each layer runs at right angles to the layer above and below it.

This makes it stronger than particleboard, because timber fibres are very strong in the direction of their grain, and by alternating the layers the strength is spread in all directions.

Audio for slide 8 (mp3 |6|KB)

Audio for slide 8 (mp3 |6|KB)

Once it has been pressed and allowed to cool, the sheets are trimmed to size.

Like particleboard flooring, plywood flooring has a groove machined into both long sides, with a plastic tongue inserted into one side.

Learning activity

Audio for slide 11 (mp3 |6|KB)

Audio for slide 11 (mp3 |6|KB)

For more information on particleboard and plywood, go to the Engineered Wood Products Association of Australia (EWPAA) website. If you click on the 'Library' menu link, you will see a wide range of downloadable technical guides, fact sheets and video clips.

Have a look now at the topics available and follow up on the ones that interest you.

Go to Underlay board products

Go to Underlay board products