Other moisture testing methods

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

Capacitance test

Capacitance moisture meters use radio waves to measure the moisture content inside the material being tested.

They have in-built transmitting and receiving pads which pass the radio wave through the material and measure the capacitance, which is directly related to the amount of water present.

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

They're used on a wide range of materials, including concrete, wood, vinyl and ceramics.

For timber floors, they are a quick and easy way to measure moisture, although they're generally not quite as accurate as electrical resistance meters.

They also require a correction factor for different timber densities, because of the effect that density has on the way radio waves travel through the wood fibres.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

This is because the radio waves only penetrate to a depth of about 25 mm.

They can also show false readings in concrete if there are additives or large pieces of aggregate or reinforcing steel near the surface.

Although capacitance meters are accepted by the Australian Standards as an approved way of testing timber, they are not permitted for concrete.

Nonetheless, they are still a useful tool for finding out where the wetter areas are in a concrete floor so that you know where to drill the test holes for sensor probes.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

Calcium chloride test

The calcium chloride test was once considered standard practice in America for determining moisture levels in concrete floors, and was written into the American Society for Testing and Materials (ASTM) Standard.

However, over the years many of the floors that were originally assessed as acceptable with this test were later found to have developed moisture problems.

As a result it has fallen out of favour with flooring installers and has now been removed from the ASTM Standard for testing lightweight concrete. It is also no longer permitted under AS 1884-2012.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

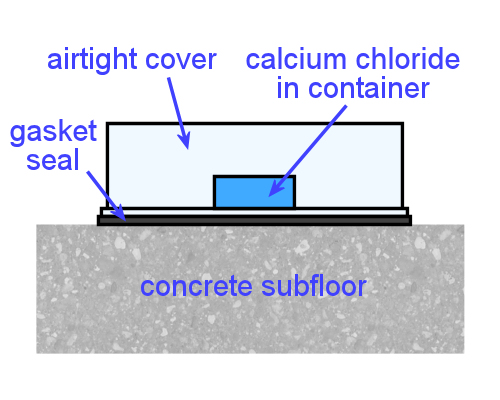

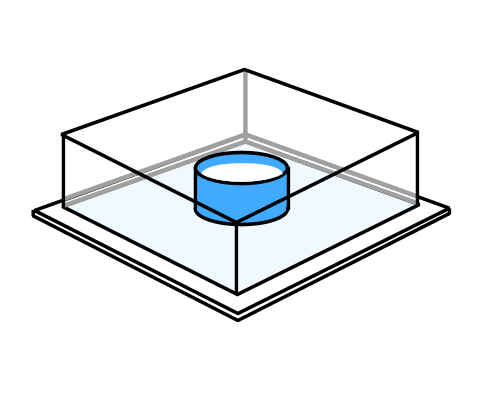

In this test the moisture is absorbed in a small mound of calcium chloride salt, which is placed on the concrete surface and sealed with a plastic dome.

The increase in weight of the salt is used to calculate the relative humidity in the slab.

The biggest problem with the test is that it can only measure the rate of moisture loss in the very top of the slab, and can't take account of the higher concentrations deeper down.

It also tends to underestimate moisture levels that are high and overestimate levels that are low.

Learning activity

Audio 6 (mp3 |6|KB)Wagner Electronics have produced a video clip that explains the problems with the calcium chloride test. You can see it by clicking on the link below.

Although the capacitance meter also has its problems, it is still widely used for quick moisture checks, especially when you're looking for the most appropriate places to put an in-situ probe.

Have you used a capacitance moisture meter before?

What brand was it?

If you haven't used one before, do you know of any other capacitance meter manufacturers?

Go to Measuring pH levels

Go to Measuring pH levels