Concrete surface profiles

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

The International Concrete Repair Institute has developed a set of guidelines for assessing a concrete surface profile (CSP), ranging from CSP 1 (nearly flat) to CSP 9 (very rough).

Follow the link below to see an information page from Floorex showing a photo for each profile and giving an example of the processes used to achieve it.

Surface profile guide

Follow the link below to see an information page from Floorex showing a photo for each profile and giving an example of the processes used to achieve it.

Surface profile guide

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

Chemical reactions are produced when detergents or acids are used to remove surface contaminants.

Most chemical washes don't have any effect on the CSP.

However, there are various cautions that apply, especially in neutralising and hosing off the acid wash with water.

You must also ensure that the slab is allowed to dry out to a relative humidity level that's safe for installing a floor covering.

For more details, see 'Preparing concrete substrates' (in Subfloor coatings and toppings).

Most chemical washes don't have any effect on the CSP.

However, there are various cautions that apply, especially in neutralising and hosing off the acid wash with water.

You must also ensure that the slab is allowed to dry out to a relative humidity level that's safe for installing a floor covering.

For more details, see 'Preparing concrete substrates' (in Subfloor coatings and toppings).

Learning activity

Audio 8 (mp3 |6|KB)Let's go back to the Surface profile guide we looked at earlier and examine the photos in more detail.

From what you know about the different processes used to create these CSPs, what characteristics can you see that makes each one distinctive?

In particular, what is it about the surface texture of the following processes that makes that type of concrete removal distinctive?

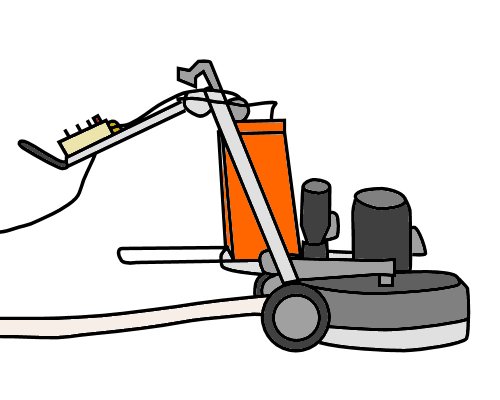

- Grinding - CSP 2

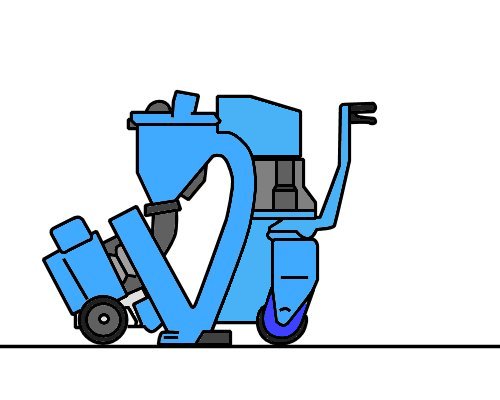

- Shotblasting - CSP 3 and 5

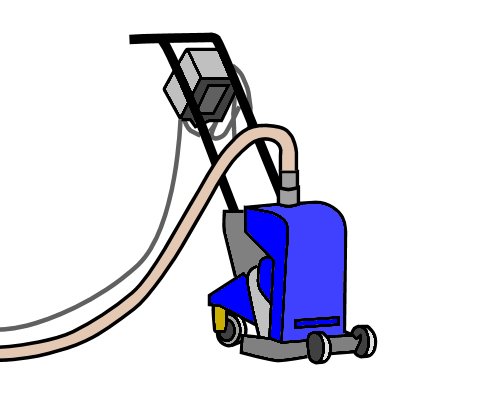

- Scarifying - CSP 4, 6 and 9.

Go to Types of grinders

Go to Types of grinders