Motifs and patterns

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

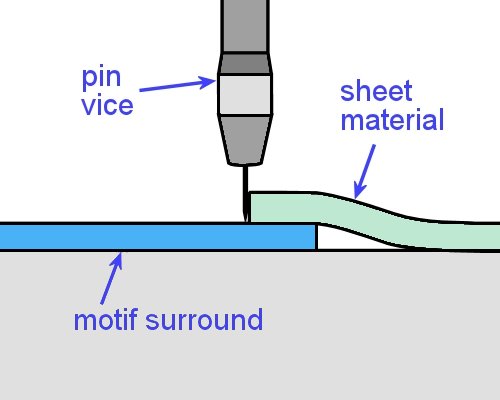

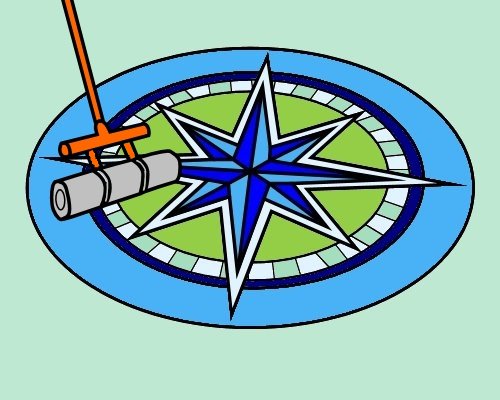

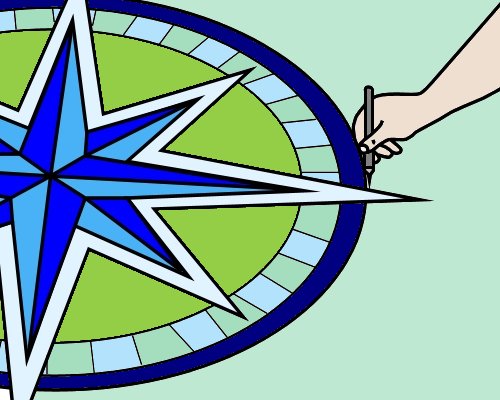

The processes used to insert motifs and make custom-designed patterns are similar in principle to those used for borders and feature strips.

Most motifs these days are delivered to the site preassembled.

They may already be inset into a surround that can be re-trimmed to size.

Alternatively, they could be pre-cut to the precise finished shape.

Most motifs these days are delivered to the site preassembled.

They may already be inset into a surround that can be re-trimmed to size.

Alternatively, they could be pre-cut to the precise finished shape.

Audio for slide 8 (mp3 |6|KB)

Audio for slide 8 (mp3 |6|KB)

Here are some hints on installing site-cut patterned floors:

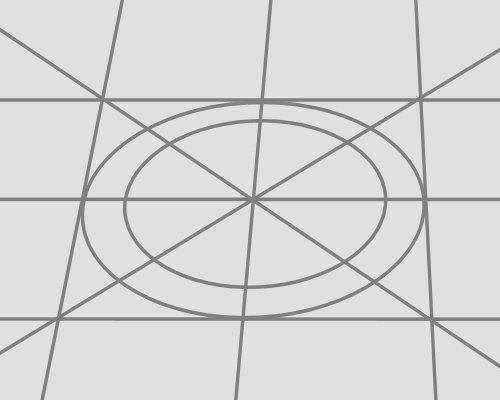

- Before you start, work out where any seams will go and make sure the client agrees with their positioning. Note that this may affect the material wastage, so it's best done at the quotation stage of the job.

- Agree with the client on the orientation of patterns and the direction of individual features.

- Mark out the design on the floor, including the centre points of circles or curves, to ensure that the assembly goes exactly to plan.

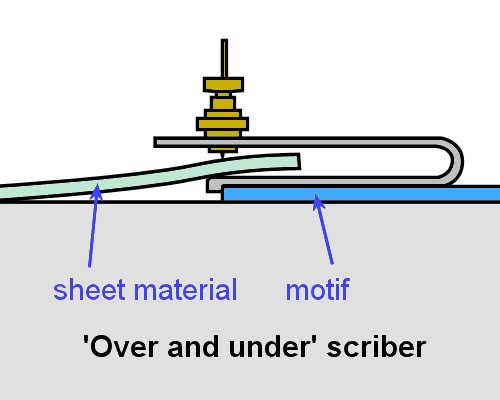

- Use a recess scriber to scribe adjoining pieces.

Learning activity

Audio 9 (mp3 |6|KB)Have a look at the promotional video produced by Polyflor at the link below.

Education flooring from Polyflor

As you watch the different designs, think about the steps that would have been involved in setting them out and fitting the individual pieces.

We'll talk more about geometry and set-outs in the unit: Resilient tiles.

You should also speak to your supervisor or another experienced installer about the motifs or customised patterns they have installed.

What were the designs?

How did they go about setting out and installing them?

Go to Assignment

Go to Assignment