Insulated hood test

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

The traditional synthetic hair hygrometer has a hair that changes length in response to the RH level. The length is measured by a gauge on top of the unit.

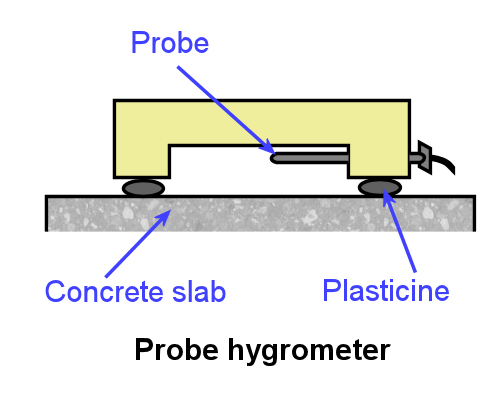

A more modern variation uses a moisture-sensitive probe inside the sealed box. This is attached to an electrical cable that can be connected to an external unit with a digital readout.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

Using a relative humidity probe and insulated hood

For slabs at ground level or below, it's best to place one hygrometer in the centre of the room and others within one metre of all exterior walls where floor coverings will be laid.

Carry out as many tests as needed to meet the requirements of the Standard.

In particular, choose areas that might be susceptible to high readings, such as entryways and walls near garden beds.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

Remove all traces of curing compound, adhesive residue, and anything else that might impede the free flow of vapour.

You can check that there's no burnished or non-porous surface material by doing the 'water drop' test - see. Inspecting concrete subfloors.

Once it's clean and free from dust, leave the test area exposed for at least 24 hours.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

Some installers use plumbers putty, others use several layers of insulation tape. Either way, it's important that the seal is completely airtight.

Leave the hood in place for at least 72 hours.

Note that if the slab is 200 mm thick or more, or if it has a low porosity, you might need to wait a lot longer than 72 hours for the air chamber inside the hood to reach moisture equilibrium.

In these situations it might be better to use the in-situ probe test.

Learning activity

Audio 7 (mp3 |6|KB)There are lots of YouTube video clips produced by the manufacturers of moisture testing equipment. These videos are designed to promote the company's own products, so naturally they show them in the best possible light. However, as long as you keep this in mind, the videos are very helpful in demonstrating how particular systems work.

The link below will take you to a clip produced by Tramex demonstrating their 'Hygrohood'.

Have you used the hood method to measure RH in a slab? What brand of hygrometer did you use? If you haven't used one before, do you know of any other manufacturers of hygrometers? Find out as much information as you can about the hygrometer you'll be using in preparation for the practical assessment demonstrations.

Share your answers with your trainer and other learners in your group.

Go to In-situ probe test

Go to In-situ probe test