Timber framed subfloors

Audio for slide 1 (mp3 |6|KB)

Audio for slide 1 (mp3 |6|KB)

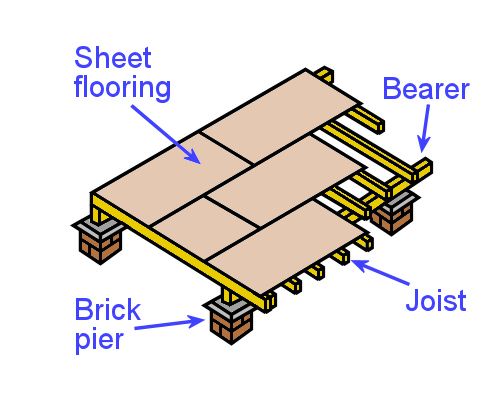

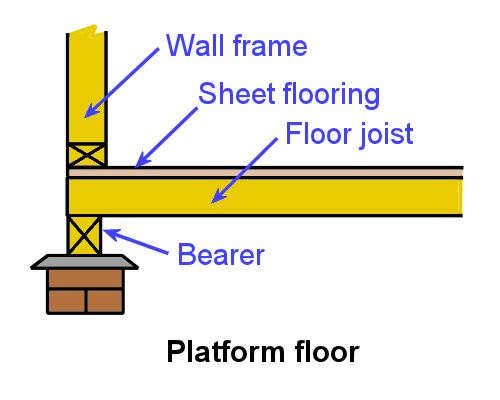

In ground floor construction the joists rest on bearers, which in turn are supported by brick piers, timber stumps or some other column or wall.

Occasionally steel framing is used for the bearers and joists, but the same structural principles apply.

Audio for slide 3 (mp3 |6|KB)

Audio for slide 3 (mp3 |6|KB)

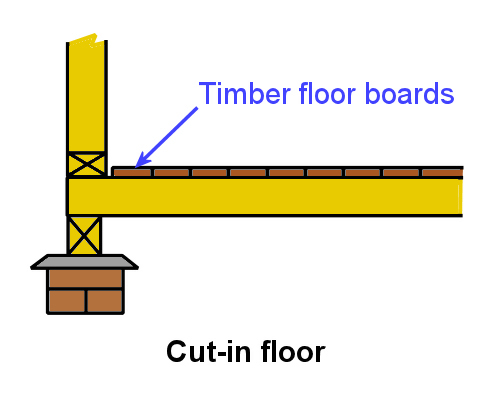

This is the traditional technique used in cottage construction when floors were generally made of tongue and groove timber boards.

The walls sit directly on the floor joists and are erected before the floor boards are installed.

Although it's harder work for the builders, it has the advantage of allowing the roof to be covered and the building waterproofed before the floor boards go down.

So the technique is still used for tongue and groove strip flooring that's fixed directly to the joists.

Audio for slide 5 (mp3 |6|KB)

Audio for slide 5 (mp3 |6|KB)

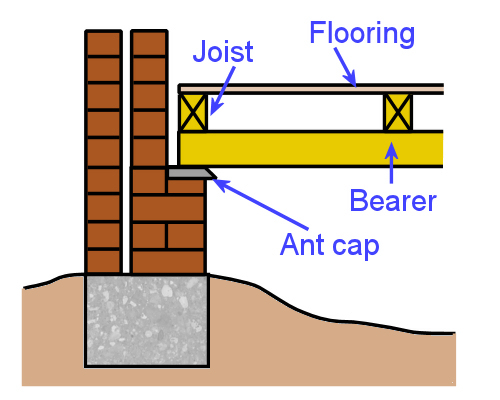

Ant caps are made from galvanised steel or some other durable metal.

However, they are also protected from corrosion by a layer of DPC that's placed immediately underneath, on top of the brick pier or wall.

Audio for slide 6 (mp3 |6|KB)

Audio for slide 6 (mp3 |6|KB)

That's why these joists are generally 'deeper' (that is, have a greater size across the width of the piece), or are made from engineered products.

They also become the ceiling joists for the rooms below, which means they can be closed in on the underside with plasterboard or other types of sheet products.

Learning activity

Audio for slide 7 (mp3 |6|KB)

Audio for slide 7 (mp3 |6|KB)

Traditionally, bearers and joists in timber framed buildings were always solid timber. Ground floors typically used hardwood, and upper floors used oregon (also called Douglas fir) because of its excellent strength-to-weight ratio.

These days, however, the availability of timber species has changed a lot. Australian hardwoods and imported oregon are much more expensive and in shorter supply, while plantation pines have become readily available and more economical.

In addition, there are many engineered products now on the market that are suitable for use as joists or beams.

Can you name three different engineered products used as floor joists? What materials are they made from and what components are used in their structure?

(If you have trouble coming up with the names of three products, have a look at the website for the Engineered Wood Products Association of Australia. This site contains a lot of information on these types of products.)

Go to

Go to